- Mobile: +86-17898840146

- Tel: +86-21-6840-8185/8186

- E-mail: info-vs@vostosun.com

- Capacity (t/h): 4~100

- Coal consumption(g/T): 6~14

- Model range: ⌀2.0×4 ~ ⌀4.0×10

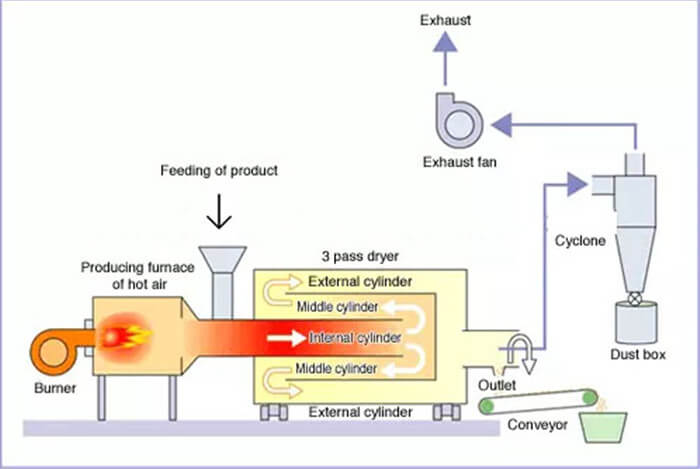

Working Principle

1. Materials will be constantly lifted up by lifting boards, and scattered in spiral type to make hot exchange

2. And then, material will be moved to middle layer of drum for countercurrent drying, and materials in middle layer of drum will be constantly lifted up by lifting boards. Materials in middle layer of drum can both full absorb heat generated by inner drum layer, and heat generated by middle drum layer, while extend drying time, so materials reached its nest state in this process

3. Material can move to the outer drum layer from the middle drum layer, material reached the drying effect will be discharged fast along with hot air, while wet materials have not meet the drying effect can’t move quickly due to high weight, so wet materials can get adequate drying to reach drying effect thus achieve to complete the drying process

|

Model |

Capacity (t/h) |

Coal consumption(g/T) (Dry) |

Power (KW) |

|||

|

Slag |

Fly ash |

Clay |

Yellow sand |

|||

|

⌀2.0×4 |

5~10 |

4 |

4~6 |

10~15 |

12~14 |

11 |

|

⌀2.0×5 |

10~15 |

6 |

6~8 |

15~20 |

12~14 |

11 |

|

⌀2.5×5 |

20~25 |

8 |

8~12 |

20~25 |

10~12 |

15 |

|

⌀2.5×6 |

25~30 |

10 |

12~15 |

25~30 |

10~12 |

15 |

|

⌀2.8×6 |

30~35 |

15 |

15~20 |

35~40 |

10~12 |

22 |

|

⌀3.0×6 |

35~40 |

20 |

20~25 |

40~45 |

8~10 |

30 |

|

⌀3.0×7 |

40~45 |

25 |

25~30 |

45~50 |

8~10 |

30 |

|

⌀3.2×7 |

45~50 |

30 |

30~35 |

50~60 |

8~10 |

44 |

|

⌀3.2×8 |

50~60 |

35~40 |

35~40 |

60~70 |

6~8 |

44 |

|

⌀3.6×8 |

60~70 |

40~45 |

40~45 |

70~80 |

6~8 |

60 |

|

⌀3.8×9 |

70~80 |

45~50 |

45~50 |

80~90 |

6~8 |

60 |

|

⌀4.0×10 |

80~90 |

50~60 |

50~60 |

90~100 |

6~8 |

74 |