- Mobile: +86-17898840146

- Tel: +86-21-6840-8185/8186

- E-mail: info-vs@vostosun.com

- Ore name: Feldspar

- Application: hematite, limonite, siderite+,

- ilmenite, chromite, wolframite, tantalum-niobium, And etc

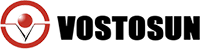

TLGT series Vertical ring and pulsating high gradient magnetic separator utilizes the combined force field of magnetism , pulsating fluid and gravity to continuously beneficiate fine weakly magnetic minerals. It is equipped with unique pulsating mechanism and possesses the advantages of large beneficiation ratio, high recovery, and a matrix that does not easily clog.

VOSTOSUN as a high gradient magnetic separator manufacturer, has provide the materials processing equipment and materials processing service for many years. TLGP high gradient magnetic separator, also named HGMS,VPHGMS, high intencity magnetic separator, feldspar magnetic separator, silicon sand magnetic separator, hematite magnetic separator, etc.

For processing fine, feebly magnetic minerals, such as hematite, limonite, siderite+, ilmenite, chromite, wolframite, tantalum-niobium, and etc. For purifying (iron and titaniun removal) nonmetallic minerals such as quartz, feldspar, nepheline, fluorite, ceramic, material, and etc.

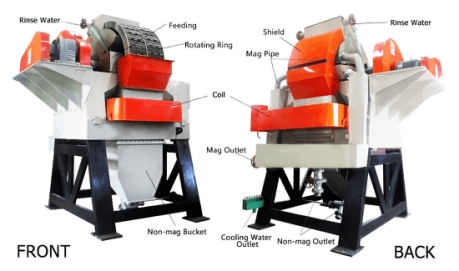

Working principle:

The TLGT vertical ring high gradient magnetic separator consists of pulsation mechanism, excitation coil, iron yoke and rotary ring. The rotating ring is made of 1 piece central ring plate, 2 side ring plates and several trapezoidal partitions with ordinary stainless steel, and a total of near 70 sorting rooms. When, swivel turn clockwise, pulp from feed to into, the feng up the iron yoke cracks through the swivel, pulp of magnetic particles in magnetic dielectric surface, turn by the band to the top without magnetic area, wash water bucket into concentrate; Non-magnetic particles flow into the balance payment bucket along the lower iron yoke.

Futures:

•Adjustable magnetic field,

•Vertical ring,

•Optimized magnetic yoke combination

•Unblocked matrix,

•High processing efficiency,

•High energy efficiency.

•High recovery,

•Mminimum processing particle size

1. Material trace:

The material to be selected is fed from the feed port. In the yellow magnetic field, the magnetic separation material is adsorbed on the surface of the magnetic medium mounted on the ring, and the nonmagnetic material flows down through the ring and flows out of the non-magnetic material outlet. The magnetic material rotates along the rotating ring to the upper part of the equipment and flows into the magnetic material under the action of unloading water.

2. Sorting interval

In the case of the coil and the yoke, a very strong background magnetic field is generated in the yellow magnetic field, and the magnetic medium induces a strong high gradient separation magnetic field in this background field strength. This sort of magnetic field produces a strong suction for the material.

3. Rinse water effect:

Rinse water can be adsorbed on the magnetic medium relative to the relatively weak magnetic particles into the non-magnetic material access, thereby improving the purity of magnetic materials.

4. The role of pulsation:

Non-magnetic material inside the slurry by the role of pulsating box so that the slurry in the yoke to do up and down reciprocating motion, immersed in the slurry under the liquid medium of the selected material in the pulsating fluid force under the action of the entire sorting process In the loose state, which effectively eliminates the inclusion of materials and significantly improve the purity of magnetic materials, and inhibition of mineral particles to block the phenomenon of magnetic media pray a certain role.

|

Ore name |

Magneti Separator Model and QTY |

Feed grade (Fe) |

concentrate grade(Fe) |

Iron Recovery(Fe) |

|

Magnetite /hematite |

TLGT-1750,6sets |

30.15% |

67.5% |

76% |

|

Magnetite /hematite |

TLGT-2000,15sets |

30.5% |

67.50% |

76.07% |

|

Hematite |

TLGT-1750,9 sets, TLGT-1500,4sets |

45% |

60% |

76% |

|

Iron ore |

TLGT-2000,5 sets, TLGT-1750,5 sets, SLon-1500,5sets, |

51.09% |

64.57% |

88.01% |

|

Hematite |

T-1750,2sets |

55.2% |

65.09% |

86.39% |

|

Ore name |

Magneti Separator Model and QTY |

Feed grade (Fe) |

concentrate grade (Fe) |

Iron Recovery (Fe) |

|

Feldspar |

TLGT-2000 |

0.49-0.64% |

0.15-0.18% |

90% |

|

Feldspar |

TLGT-2000 |

1.48% |

0.26% |

90% |

|

Feldspar |

TLGT-2000 |

1.69% |

0.18% |

90% |

|

Feldspar |

TLGT-2000 |

0.1% |

0.02% |

90% |

|

Feldspar |

TLGT-2000 |

1.5% |

0.03% |

90% |